HDV Wash Systems Sales

Industrial Machine Installation (IMI) delivers turnkey Heavy-Duty Vehicle Wash Systems for trucks, buses, trains, and specialty vehicles. We work hand-in-hand with leading wash system manufacturers to consult, sell, install, and launch complete solutions tailored to each site.

From initial planning through final commissioning, IMI manages every step—ensuring seamless coordination, expert installation, and dependable system performance from day one.

HDV Wash Systems Installation

Industrial Machine Installation is the trusted partner for Heavy Duty Vehicle Wash Systems engineered by leading OEMs. We specialize in the installation of heavy-duty truck, train, and specialty wash equipment designed for performance and durability. Our certified team brings deep industry experience, lean/agile project management, and a commitment to extreme ownership on every project. From new builds to retrofits, we ensure your equipment is installed right the first time—safely, efficiently, and to spec.

HDV and Car Wash Systems Parts & Services

Industrial Machine Installation (iMi) provides reliable parts and service support for both car wash systems and Heavy-Duty Vehicle Wash Systems, including trucks, buses, and trains. Whether you’re running a high-volume tunnel wash or a fleet-focused drive-through system, we help keep your equipment running at peak performance.

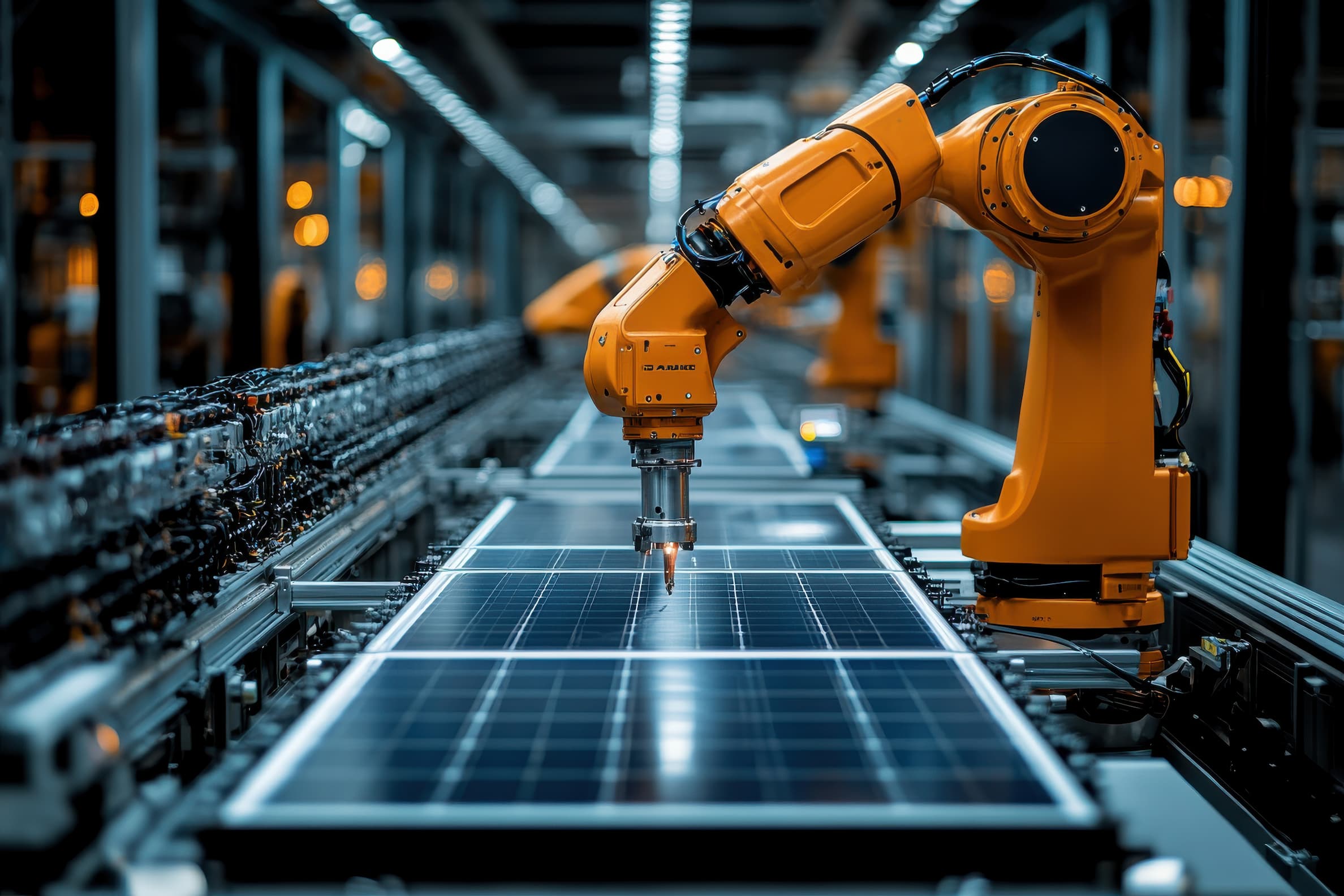

Robotic Systems

Industrial Machine Installation (iMi) is your go-to partner for the expert installation of robotic systems from trusted names like FANUC, Kawasaki, Yaskawa/Motoman, and ABB. We specialize in turnkey robotic cell installations for paint, welding, and material handling—particularly in demanding automotive OEM and Tier 1 production environments.

From structural steel and cell layout to final robot placement and commissioning, our certified crews deliver precision, safety, and speed. With deep industry experience, lean project management, and a commitment to extreme ownership, iMi minimizes downtime and maximizes performance.

When it’s time to install high-performance automation, iMi delivers with confidence and capability.

Finishing Systems

Industrial Machine Installation (iMi) specializes in the professional installation of finishing system equipment—including paint booths, ovens, and conveyors—manufactured by industry leaders like Sames, Graco, Binks, Wagner, and Gema. While we don’t engineer or design systems, we work closely with OEMs, general contractors, and end users to install complex finishing systems safely, efficiently, and to spec.

Our experienced crews handle everything from structural placement to mechanical assembly and utility tie-ins. Whether you’re adding a single booth or building out a complete line, iMi ensures each component is installed with precision, aligned for optimal flow, and ready for commissioning.

We support projects in automotive, general industrial, and heavy equipment sectors—with a focus on quality craftsmanship, site safety, and schedule adherence.

When it’s time to install finishing systems that perform, iMi is ready to go to work.

Custom Machinery

Industrial Machine Installation (iMi) delivers expert support for industrial and commercial equipment installations, offering end-to-end solutions from unloading and rigging to mechanical, electrical, plumbing, and pipefitting (MEP) work. Serving general contractors, OEMs, and facility owners, iMi supplements on-site teams with skilled, safety-focused

tradespeople experienced in complex industrial environments.

Our Services Include:

- Custom Machinery Installation: Precise setup of equipment such as pump skids, robotic automation cells, conveyors, tanks, and process machinery—from floor-level bolting to overhead rigging.

- Mechanical Installation: Assembly and placement of structural steel, machinery, and mechanical systems to engineered specs.

- Electrical Support: Installation of conduit, control panels, cable trays, and field wiring, working alongside licensed electricians as required.

- Plumbing & Pipefitting: Installation of water, air, and process piping systems, including threaded, welded, and press-fit lines, all executed to code.

Whether it’s a single machine or a fully automated production line, iMi scales with your project to keep timelines, budgets, and safety goals on track—delivering high-quality results the first time, every time.

Lifting and Rigging

Industrial Machine Installation (iMi) provides certified lifting and rigging services for industrial and commercial projects across the U.S. Our team includes NCCCO-certified operators (up to 75 tons) and Level 2 certified riggers, giving you the confidence that every lift is executed with safety, precision, and full regulatory compliance.

We offer lifting and rigging as a standalone service or bundled into our machine installation, system integration, or wash system projects. Whether it’s a routine equipment set or a complex, high-stakes lift, we’ve got it covered.

Services include:

- Equipment lifting up to 75 tons

- Certified rigging and signaling

- Lift plans, engineered lift plans, and PE-stamped lift plans

From concept to completion, iMi ensures your critical lifts are safe, compliant, and on schedule.